Reasons To Invest

Food Recycle is an Australian technology start-up, commercialising our mission to tackle the global food waste problem.

-

Patented Technology and know-how. Food Recycle’s patented technology and know-how licensing program turns one of the world’s most wasted resources - food waste, into valuable animal feed.

-

First mover advantage. With our unique process, we overcome barriers of biosecurity - a previous roadblock that has limited the reuse of food waste.

-

Cost Stability. We introduce cost stability to the agriculture and aquaculture industries, as our feed is not dependent upon global trade prices of soybean, corn and other ingredients.

-

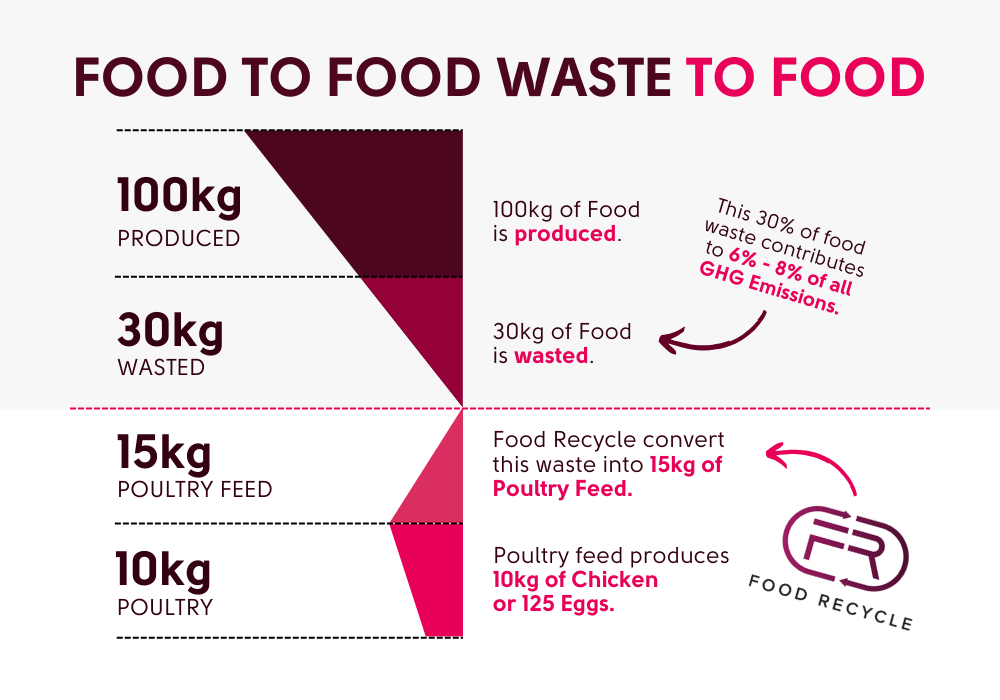

Environmental & Sustainability aligned. With 92% of food waste going to landfills, we close the environmental loop. We can repurpose 100% of commercial food waste and turn this into a range of animal feeds of equal to, and in some cases outperforming commercially available feeds. (1)

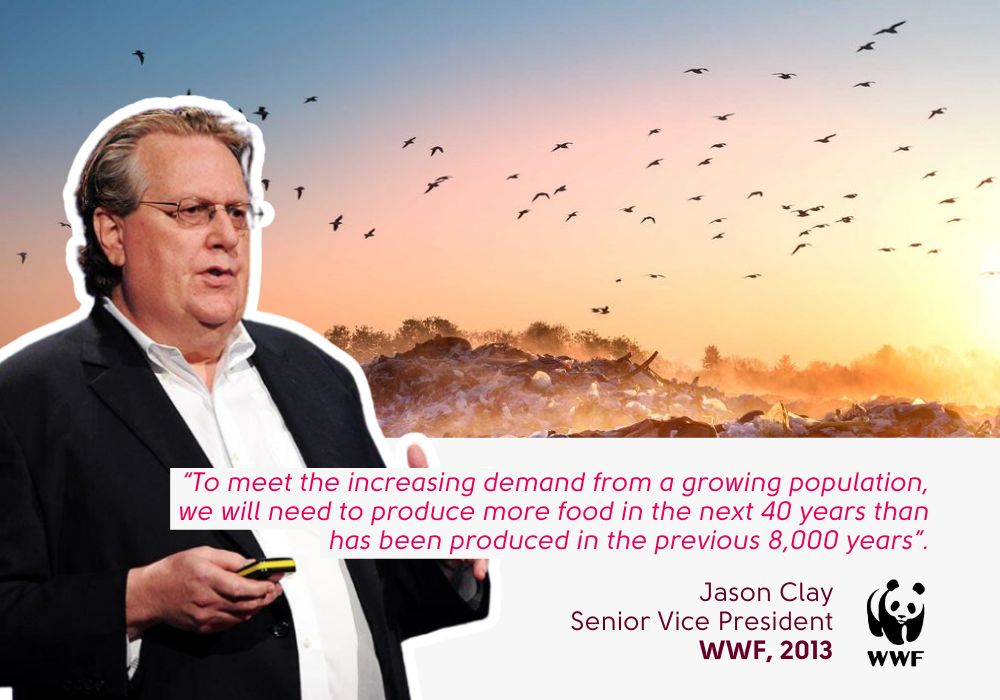

- Increasing demand in a non-discretionary market. Food production needs to rapidly increase to stay on track with population growth and current farming practices cannot scale to meet this demand. Our solution will greatly contribute to the production of animal feed, whilst also significantly reducing greenhouse gas emissions from landfills and farming.

The Problem

In 2009, the Food and Agriculture Organisations of the United Nations (FAO) estimated that food production will need to increase by 70% by 2050 to keep up with population growth. (2)

Meanwhile, in Australia, the CSIRO identified food waste and food insecurity as growing challenges for Australia. Consequently, there is an urgent need for a circular solution to reuse food waste with innovative new products. (3)

The Key Statistics:

-

One-third of all human food produced is wasted, with up to 92% of commercial food waste deposited in landfills. This waste contributes to significant food security issues and depletes global resources. (4)

-

Current animal feeds significantly contribute to carbon footprint, accounting for 35% of the carbon footprint of 1 kg of chicken meat and 76% of the carbon footprint of eggs. (5)

-

Global demand for food is increasing rapidly. Leading experts believe we will run out of existing food sources by 2050. (6)

The Solution

We have a solution to reshape Australia’s food systems:

Food Recycle operates at the forefront of the renewable food resources sector and waste diversion economy.

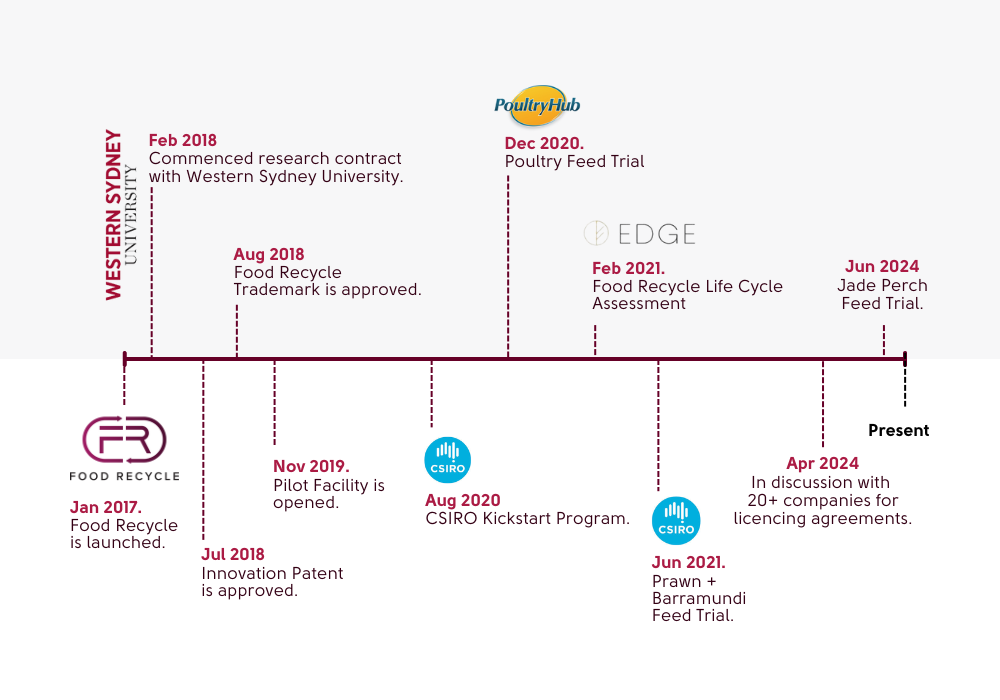

Partnering with the CSIRO and the University of New England we have completed 4 successful feed trials, demonstrating our technology and know-how to convert commercial food waste into high-performance animal feed.

Because we use food waste for its valuable and primary purpose (food) our solution can address global problems with food waste and food security simultaneously.

- Process 100% of commercial food waste.

- Increase food security.

- Close the loop on food waste.

- Reduce methane emissions.

- Treat all biosecurity risks associated with food waste.

- Ensure cost stability for commercial feeds by bypassing global commodity price fluctuations.

Governments across Australia are implementing bans to encourage businesses to divert their food waste from landfills, creating a national incentive for our innovative technology and licensing model.

Our Milestones:

- Opened our operational pilot facility located in Bega Valley for testing and calibration with Western Sydney University. This facility produces the feed for the Univesity of New England and CSIRO animal feed trials.

- Completed a three-year research contract with Western Sydney University, analysing and data-basing 25 new food waste streams.

- Authored a comprehensive Food Waste Resource Report for Australia.

- Presented at the CSIRO Future Protein Conference in Sydney.

- Developed an engineered design for a standard 100-ton-per-day feed output production facility.

- Conducted four successful animal feed trials with CSIRO and the University of New England.

- Completed 4th feed trial with the CSIRO, the latest focused on Australian Jade Perch at the CSIRO research facility on Bribie Island.

- Featured in prestigious publications like Forbes ‘Inclusive Capitalism’ for challenging the status quo and creating a purpose-driven company.

Our feed trials, conducted on layer hens, prawns, barramundi, and Australian Jade Perch, have demonstrated that Food Recycle feed is comparable, and in some cases superior to Commercial Feeds. For example, our barramundi trial showcased that a 67% food waste inclusion diet improved barramundi weight gain by 35%. (9)

Business Model:

Our scalable technology is capital-light and can be implemented through a straightforward licensing program that gives licensees access to:

Our patented technology and know-how.

- Our research and development (R&D).

- Our engineering resources.

- Our waste profiling teams.

- Our feed formulation app.

The Food Recycle licensee has the rights under the licensing agreement to utilise our patented technology and the know-how for Australia and New Zealand and will be required to use the Food Recycle equipment and technology. It is expected that only one Technology and Knowhow Licensee will be appointed for Australia and New Zealand, as the license is exclusive. The licensing agreement will require the appointed licensee to have built and made operational 25x 100-ton production facilities within 15 years, with the first 10 of those 25 facilities built within 10 years. Should the licensee not meet the production facility development targets Food Recycle will have the right to revoke the exclusivity for Australia and New Zealand.

This process ensures that our equipment and feed quality are maintained through a controlled environment. The Food Recycle model provides a turn-key production facility and includes operational staff training, food waste collection training and technology upgrades.

Each production facility built will be contracted (under the provisions of the licensing agreement) to the appointed licensee at the current Turn-Key price of $32 million. The cost to complete each facility including all support requirements is $17 million, resulting in a gross profit of $15 million.

Under this model, Food Recycle generates income from:

- The build of the 25 production facilities over 15yrs,

- Royalties of 4.5% on feed sales in perpetuity,

- 80% of the income from traded carbon credits for the diversion of food waste from landfill in perpetuity.

- The production facility is designed to have an operational capacity of 100 tons per day (output) with an allowance to operate at 85% capacity (therefore 85 tons per day). Designed to operate 7 days a week 365 days per year (food waste is collected and therefore processed every day), resulting in a total annual production of 31,000 tons.

At an average per ton sale of $550, each production facility's annual revenue would be $17 million.

Royalties in accordance with the licensing agreement are 4.5% of the tonnes sold by the licensee with the tonnage linked to the commercial sale value of the feed. For a licensee with sales of 31,000 tons per year at a market value sale price of approx $550 per ton, the Royalty will be 4.5% of $17 million, equating to $765,000 per production facility per year paid quarterly*.

*Please note that whilst the figures used in this example are indicative of our production capacity and market rates, these are not financial projections.

Food Recycle International has already appointed two licensees internationally and negotiations are taking place for licensing in 27 other countries.

Our Process:

Our five-step process involves:

Step 1: Food Waste Collection.

Each waste producer is profiled into a category based on the average nutritional profile of their waste. The food waste is collected from the waste producer and kept separate from other waste of the same profile.

Step 2: Processing.

Each waste stream is processed separately through the facility. This includes a biosecurity step that kills every known pathogen associated with food waste.

Step 3: Storage & Measurement.

Once processed, each waste stream is stored in silos as a dry granulated powder. Each silo's content is then tested for its nutritional content and amino acid profile.

Step 4: Mixing.

Multiple ingredients from different silos are then mixed with any required micro-ingredients for each formulation.

Step 5: Packaging.

The completed feeds are then pelletised (if required) and packaged according to their end-use.

As part of our quality testing, 4 trials have been conducted in partnership with the University of New England (UNE) and the CSIRO to validate the performance of our feeds against Control diet feeds. The feed trials to date have been conducted on layer hens at the UNE animal research facility at Armidale, and aquaculture feed trials on prawns and barramundi have been conducted at the CSIRO research facility Bribie Island QLD. More recently, Food Recycle completed the 4th trial on Australian Jade Perch at the CSIRO research facility on Bribie Island.

All feed trials concluded that the Food Recycle feed produced from food waste streams was comparable to the commercial (control) feeds used in the trial, and in some cases superior to the Control diets.

The Industry

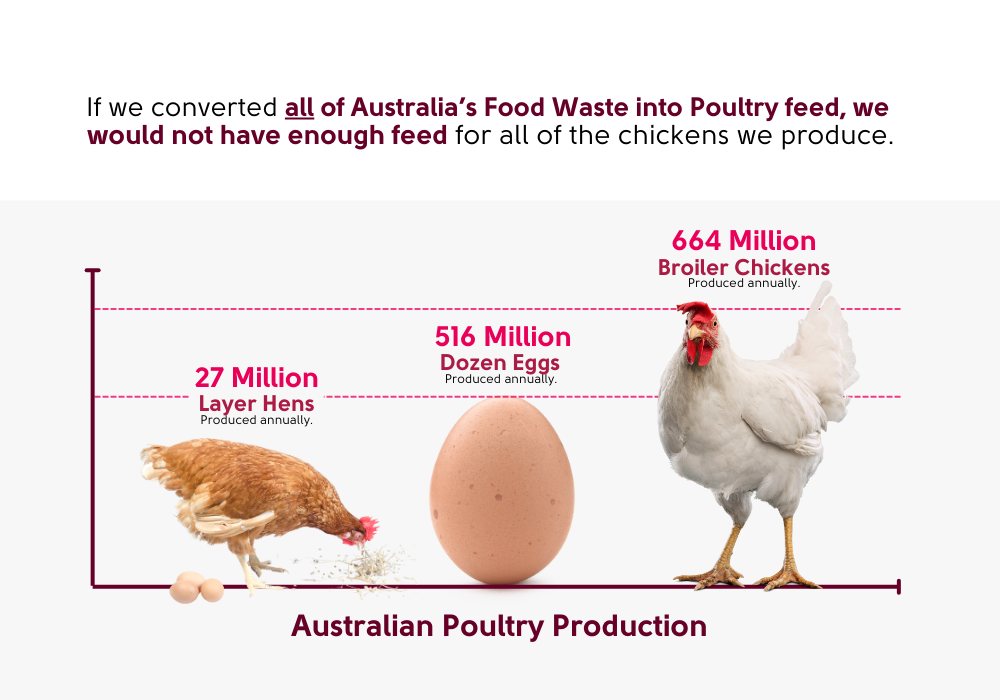

Australia has over 27 million egg-laying hens and approximately 664 million broiler chickens which consume more than 4 million tons of poultry feed annually.

Even if all commercial food waste in Australia were collected, it would not meet the poultry industry’s feed demands, let alone the needs of the pig or aquaculture industries.

The Australian animal feed market was estimated at US$4.761 billion in 2021 and will rapidly increase as population growth drives higher demand for food production. (10)

Over the past 20 years, numerous businesses have commercialised food recycling and composting, however, over 90% of food waste is still sent to landfills. (11)

The main barriers associated with converting food waste to animal feed are biosecurity and the potential contamination of food from overseas sources. Food Recycle has overcome this with our unique patented process which removes any bio-security risks to ensure the quality and safety of our feed.

We stand alone as one of Australia’s only ‘full-circle’ producers taking 100% of food waste.

Competitive Advantage:

Our technology consists of 5 key steps to convert food waste into animal feed. A fundamental point of difference in our technology is that we collect and process different waste streams separately. This enables us to store dry materials of similar nutritional value, and use them as ingredients when formulating complete feeds.

The Food Recycle production process achieves sustainability, circular economy, and food security outcomes simultaneously. Processes such as composting and anaerobic digestion or the use of black larvae fly only deliver partial benefits because they use food waste to create a byproduct whilst our process converts waste 2:1 into feed.

As a leader in the renewable waste industry, our Clinical Feed trials have produced results that speak for themselves.

Use of Funds:

Our feed trials are just the beginning. Now we want our impact to go further.

With global demand for animal feed increasing, we are launching our regional licensing program across Australia and beyond.

Funds raised will go towards:

- Our mechanical and electrical engineering system design and documentation to build our first production facility.

- Support general cash flow needs for appointing the technology and know-how licensees for Australia and New Zealand.

Risks:

Funding and Cash Flow: The Company is in the process of raising funds to achieve its strategic business objectives and to cover its projected operating expenses. The Company may not raise all of the required funding and therefore not achieve all of its business objectives. This means that the current cash reserves (plus proceeds of the Offer) may not provide the Company with sufficient working capital. Accordingly, the Company may need to obtain additional funding in the future. There is no assurance that the Company will be able to obtain additional rounds of funding on substantially the same terms as outlined in this Offer Document or at all. The Company’s value may be materially affected if the required additional funding is not available.

Dilution Risk: If, in the future, the Company undertakes further funding activities, a shareholder’s interest may be diluted (if they do not participate in future fundraising rounds).

Returns are not Guaranteed: There is no guarantee of any income distribution or capital return on the shares in the Company nor is there a guarantee of repayment of capital amounts. Shareholders will not be entitled to any guaranteed distributions of profits or capital. There is no guarantee that distributions will be at a certain level or that there will be distributions at all.

Unforeseen Expenditure Risks: Expenditure may need to be incurred that has not been taken into account in the preparation of this Offer Document. Although the Company is not aware of any such additional expenditure requirements, if such expenditure is subsequently incurred, this may adversely affect the expenditure proposals of the Company.

About Swarmer

Swarmer is an Australian equity crowdfunding platform connecting businesses and investors. Designed to support start-ups, growth companies and scale-ups we allow everyday investors to own a share in businesses that are the future. We hold Australian Financial Services License (AFS License #507867).

Find out more about becoming a shareholder via Equity Crowd Funding.